What is Stereolithography (SLA) 3D Printing?

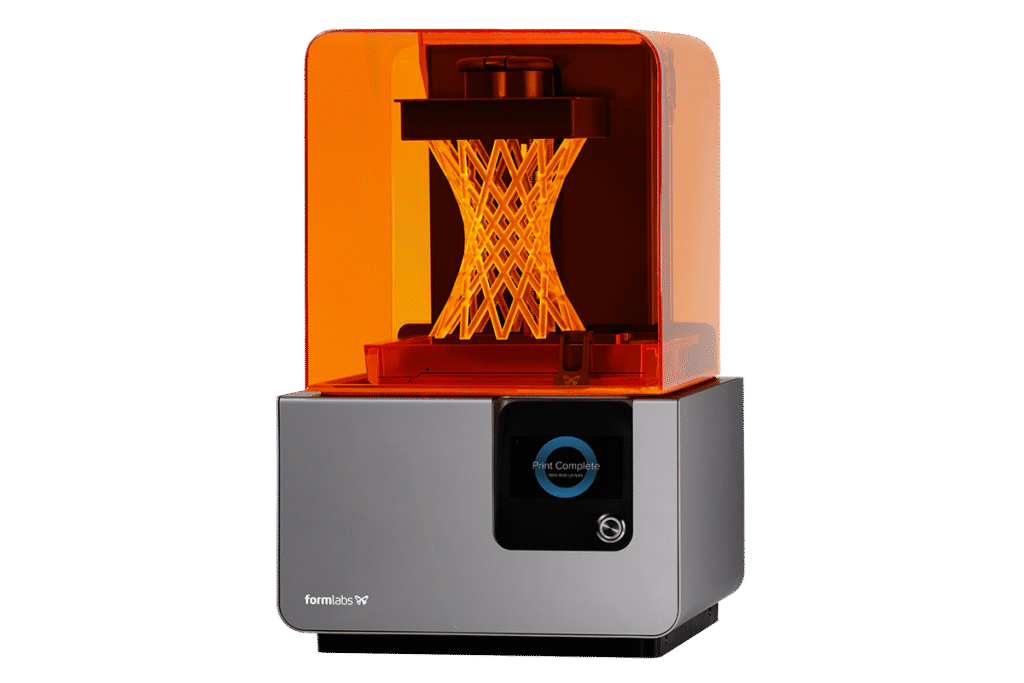

Stereolithography (SLA) is a resin-based 3D printing technology that uses ultraviolet (UV) light to cure liquid photopolymer resin layer by layer. It was invented in the 1980s, and since then, it has remained one of the most widely used methods for creating high-precision prototypes, models, and functional parts.

Unlike Fused Deposition Modeling (FDM), which extrudes thermoplastic filament, SLA relies on light-sensitive liquid resin. As a result, it achieves greater accuracy and smoother finishes, making it ideal for industries where fine details matter.

How does the SLA 3D printing process work?

The SLA 3D printing process involves several key steps:

- Design Preparation: A 3D model is created using CAD software and sliced into thin layers.

- Resin Curing: The SLA printer directs a UV laser onto the liquid resin, solidifying it layer by layer.

- Layer-by-Layer Printing: Each cured layer adheres to the previous one, gradually building the part.

- Post-Processing: Printed parts are washed to remove uncured resin and then cured further under UV light for added strength.

Therefore, SLA printers can achieve extremely fine details, high resolution (up to 25 microns), and smooth surfaces.

Materials Used in SLA 3D Printing

SLA primarily uses photopolymer resins, which come in different formulations to suit various applications. For instance:

- For general-purpose models and prototypes, use standard resin.

- Tough Resin: Gives mechanical and technical components longevity.

- Flexible resin is utilized in wearable prototypes, grips, and gaskets.

- When molds are needed, castable resin is perfect for the dental and jewelry industries.

- Biocompatible resin is appropriate for use in dentistry and medicine.

Consequently, the wide variety of resins makes SLA versatile across multiple industries.

Applications

Stereolithography is widely used thanks to its precision, smooth finish, and material versatility. Some of the most common applications include:

1. Healthcare & Dental

- Crowns, surgical guides, and dental aligners

- Anatomical models and customized prosthesis

2. Jewelry & Fashion

- SLA printing is highly accurate. In fact, it is widely used in healthcare. Additionally, it plays a major role in jewelry design

- Wearable accessories with intricate details

3. Engineering & Manufacturing

- Quick prototyping of useful components

- Fixtures, jigs, and tooling parts

4. Aerospace & Automotive

- Precision, lightweight components for testing

- Intricate geometries for validating designs

5. Consumer products

- Prototypes and designs for unique products

- Premium models, hobby parts, and miniatures

Clearly, SLA adapts well to industries that demand accuracy and professional-quality parts.

Advantages

SLA offers several benefits that make it stand out from other 3D printing methods. In particular:

- High Resolution and Accuracy – It can produce fine details and smooth surfaces.

- Wide Material Variety – Its versatility is due to the several resin types.

- Smooth Surface Finish – Requires less post-processing than FDM.

- Rapid Prototyping – Ideal for sectors that require quick iterations.

- Complex Geometries – Can produce elaborate designs that are not possible with regular production.

SLA vs. FDM: A Quick Comparison

To better understand SLA’s strengths, let’s compare it with FDM:

| Feature | SLA 3D Printing | FDM 3D Printing |

|---|---|---|

| Accuracy | Very high (25–100 microns) | Moderate (50–300 microns) |

| Surface Finish | Smooth, professional-grade | Visible layer lines |

| Material Cost | Higher (resin) | Lower (filament) |

| Durability | Moderate, depends on resin | Stronger, especially with ABS/PLA |

| Applications | Dental, jewelry, prototyping | Engineering, functional parts |

As shown above, SLA is ideal for detail and accuracy, while FDM suits durability and cost-effectiveness.

Future of SLA 3D printing

The future of SLA 3D printing looks promising. In fact, several advancements are already shaping the industry:

- Biocompatible and Sustainable Resins: For environmentally friendly and medical uses.

- Faster Print Speeds: Build times are decreased by new technologies like as CLIP (Continuous Liquid Interface Production).

- Industrial Adoption: SLA is anticipated to increase in consumer goods, healthcare, and aerospace.

- Hybrid Manufacturing: combines SLA with CNC machining and other technologies to enable enhanced production.

Conclusion

Stereolithography (SLA) 3D printing is a powerful additive manufacturing technology that offers unmatched precision, smooth finishes, and material versatility. Today, it is widely adopted in industries such as healthcare, jewelry, aerospace, and consumer goods for rapid prototyping and high-quality production.

Related Blog: Selective Laser Sintering (SLS) IN 3D Printing