What is fused deposition modeling (FDM) in 3D Printing

Fused Deposition Modeling (FDM) in 3D printing is one of the most popular and widely used 3D printing technologies in the world. Known for its affordability, simplicity, and versatility, it has become a leading choice that industries ranging from manufacturing and engineering to healthcare, education, and product design prefer. In this blog, we’ll explore what FDM is, how it works, what materials it uses, its advantages and its future in additive manufacturing.

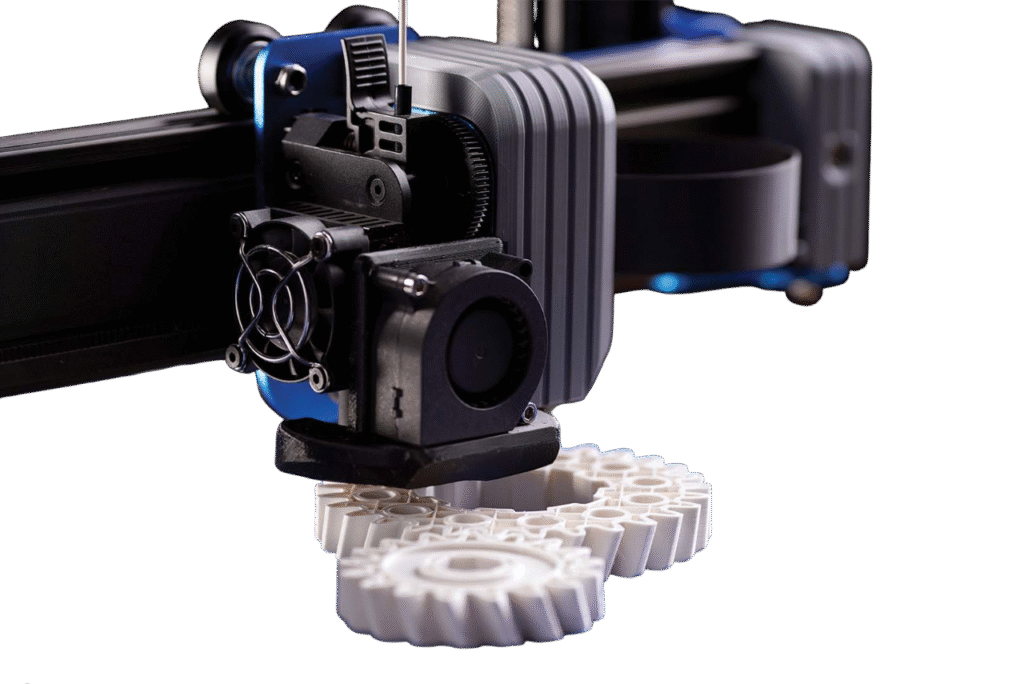

How does the FDM 3D Printing Process Work?

The FDM in 3D printing process involves:

Loading a 3D Model – Designed using CAD software and converted into STL format.

Slicing – The model is sliced into layers using slicing software.

Heating the Filament – Thermoplastic filament (PLA, ABS, PETG, etc.) is heated and extruded through a nozzle.

Layer-by-Layer Deposition – Material is precisely deposited on the build platform.

Solidification – Layers fuse together, forming a strong 3D structure.

FDM uses this layer-by-layer approach to manufacture complex designs at a minimal cost.

Materials Used in Fused Deposition Modeling (FDM)

Moreover, one of the strengths of FDM is its wide range of materials. Popular options include:

PLA (Polylactic Acid): Eco-friendly, easy to print, widely used for prototypes.

ABS (Acrylonitrile Butadiene Styrene): Strong, durable, and heat-resistant.

PETG (Polyethylene Terephthalate Glycol): Tough, flexible, and chemical-resistant.

Nylon: Strong and impact-resistant, used for industrial applications.

TPU (Thermoplastic Polyurethane): Flexible and rubber-like for functional parts.

Because of this diversity, designers can select the right filament based on strength, flexibility, and performance requirements.

Applications of Fused Deposition Modeling (FDM) in 3D printing

Furthermore, FDM is widely adopted across industries. Some key applications include:

- Healthcare : Manufacturing includes prosthesis, dental aligners, surgical models, and customised medical devices.

- Automotive: Working prototypes, light-weight car parts, jigs, and assembly tools.

- Aerospace: Lightweight components that improve fuel efficiency and reduce manufacturing costs.

- Construction: Scaled architectural models, design visualization, and structural prototypes.

- Consumer Goods: Personalized products, toys, gadgets, and household items.

- Education: Teaching aids, design prototypes, and hands-on learning tools for students.

In short, FDM bridges the gap between concept and reality, empowering industries to innovate faster.

Advantages FDM in 3D printing

Additionally, FDM offers multiple benefits that make it highly popular:

Cost-effective and accessible for both businesses and hobbyists.

Simple setup and user-friendly operation.

Wide range of thermoplastic materials (PLA, ABS, PETG, Nylon, TPU, etc.).

Ideal for rapid prototyping and functional testing.

Minimal material waste compared to traditional manufacturing methods.

Capable of producing complex geometries with strong durability.

Future of FDM in Additive Manufacturing

As 3D printing technology advances, it continues to evolve with promising innovations:

Multi-material printing to create parts with diverse properties.

Advanced filaments with enhanced strength, heat resistance, and eco-friendly characteristics.

AI and robotics integration for automated, smart production systems.

Large-scale FDM printers for construction, industrial manufacturing, and aerospace applications.

In conclusion

FDM (Fused Deposition Modeling) continues to drive innovation across industries as a powerful, reliable, and versatile 3D printing method. FDM remains one of the most accessible and scalable additive manufacturing technologies available today, whether for rapid prototyping, functional parts, or educational purposes.

Related blog :Stereolithography (SLA) IN 3d printing

Outsource :https://en.wikipedia.org/wiki/FDM_printing_file_formats