Selective Laser Sintering (SLS) in 3D Printing: Process, Applications, and Advantages

Selective Laser Sintering (SLS) is a popular technology for 3D printing and additive manufacturing. SLS is particularly popular in industries that require precision and performance because to its ability to produce high-strength, long-lasting, and functional products. Unlike traditional production processes, SLS employs a powder-based 3D printing technology that provides unparalleled design flexibility and enables the construction of complicated geometries.

What is SLS 3D Printing?

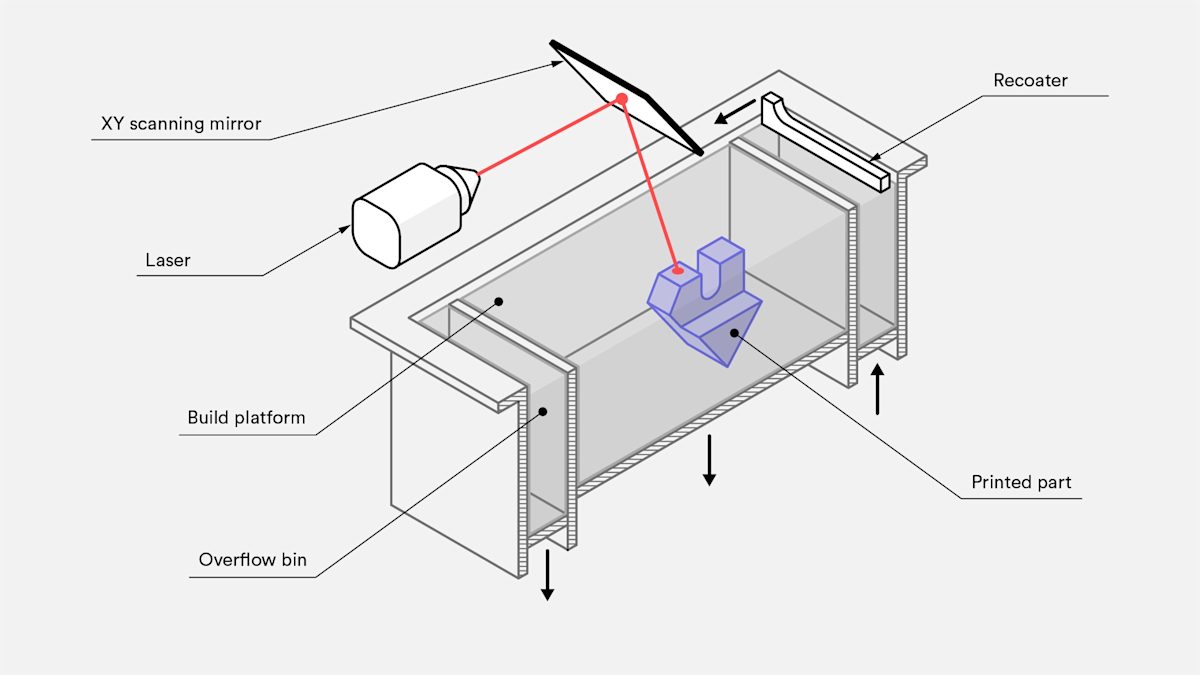

At its core, SLS 3D printing employs a high-powered laser to selectively fuse powdered materials, most often nylon, layer by layer to form a solid structure. Because no support structures are required, SLS allows for greater design flexibility, making it a perfect alternative for rapid prototyping and end-use parts.

The SLS Printing Process

The SLS additive manufacturing technique takes a straightforward yet advanced approach:

- A thin coating of powdered material is put over the build base.

- A laser selectively sinters (fuses) the particles according to the 3D model design.

- The procedure continues layer by layer until the entire item is produced.

This process produces parts with great strength, durability, and functional correctness, making SLS suitable for industrial-grade applications.

Materials Used in Selective Laser Sintering (SLS) 3D Printing

One of the reasons SLS 3D printing services are in high demand is the variety of materials available. The most common material is nylon (PA 12, PA 11), however sophisticated composites such as glass-filled nylon and carbon-fiber-reinforced powders are also employed. These materials offer heat resistance, impact strength, and durability, all of which are critical for engineering applications.

Applications of Selective Laser Sintering (SLS) 3D Printing

Because of its distinct advantages, SLS technology in 3D printing is widely used across industries such as

- Automotive: for functional prototypes and lightweight components.

- Aerospace uses high-strength, complicated components.

- Medical – for personalized prosthetics and long-lasting implants.

- Consumer products include custom designs, footwear, and functional end-use items.

Advantages of SLS in 3D Printing

SLS 3D printing offers the following advantages:

- Printed items have high strength and durability.

- Design flexibility without the necessity for support structures.

- The ability to create complex geometries with ease.

- Cost-effectiveness for small- to medium-scale industry.

- Excellent for both prototyping and end-use components.

SLS vs SLA vs FDM

| Feature | SLS (Selective Laser Sintering) | SLA (Stereolithography) | FDM (Fused Deposition Modeling) |

|---|---|---|---|

| Process | Laser sinters powdered material | UV laser cures liquid resin | Heated nozzle extrudes thermoplastic filament |

| Materials | Nylon, composites (PA 11, PA 12, glass-filled, carbon fiber) | Photopolymer resin | PLA, ABS, PETG, TPU, composites |

| Strength & Durability | High strength, durable, functional parts | High detail but brittle | Moderate strength, depends on filament |

| Surface Finish | Slightly rough, powdery finish | Smooth, high-resolution finish | Layer lines visible, rougher surface |

| Support Structures | Not required | Required | Required |

| Accuracy & Detail | High, suitable for functional parts | Very high, excellent fine details | Moderate, limited by nozzle size |

| Cost | High (industrial-grade) | Medium to high | Low (budget-friendly) |

| Best For | Industrial prototyping, functional parts, end-use products | High-detail models, dental, medical, jewelry | Hobbyists, low-cost prototyping, simple parts |

The Future of SLS Additive Manufacturing

The future of SLS additive manufacturing is bright, as companies continue to use it for production-ready parts. With improvements in materials and lower SLS 3D printing costs, this technology is likely to play an important role in altering supply chains and enabling on-demand manufacturing.

In Summary, Selective Laser Sintering (SLS) in 3D printing is a cutting-edge additive manufacturing technique that uses a laser to fuse powdered materials into long-lasting, high-strength components. SLS is widely utilized in the aerospace, automotive, healthcare, and consumer products industries due to its design freedom, complicated geometries, and rapid prototyping. With low-cost low-volume production and excellent end-use applications, SLS continues to determine the future of industrial 3D printing.

Related blog: Fused Deposition Modeling (FDM) in 3D Printing

Stereolithography (SLA) In 3D printing

Outsource: https://en.wikipedia.org/wiki/Selective_laser_sintering