What is 3D Printing?

3D printing, also known as additive manufacturing, is a process that creates three-dimensional objects from a digital model by adding material in successive layers. A digital file (like a CAD model) is sent to the 3D printer, which then builds the object layer by layer, fusing or solidifying material like plastic, metal, or resin, until the physical part is complete.

Many industries use this method for everything from product prototyping to manufacturing complex parts, and it offers advantages such as lower fixed costs and the ability to create intricate designs, that are difficult or impossible with traditional manufacturing.

How 3D Printing Works?

1. Digital Model (CAD Design)

The process begins with creating a 3D digital model using CAD (Computer-Aided Design) software. This model defines the exact shape and dimensions of the object.

2. Slicing

The 3D model is imported into slicing software.

The slicer breaks the model into thin horizontal layers and generates G-code, which gives step-by-step instructions to the 3D printer.

3. Layer-by-Layer Fabrication

The printer builds the object layer by layer. Different 3D printing methods can be used:

Melting or Sintering → Lasers or electron beams fuse powdered material into solid layers.

Photopolymerization → A light source cures and solidifies liquid resin (used in resin printers).

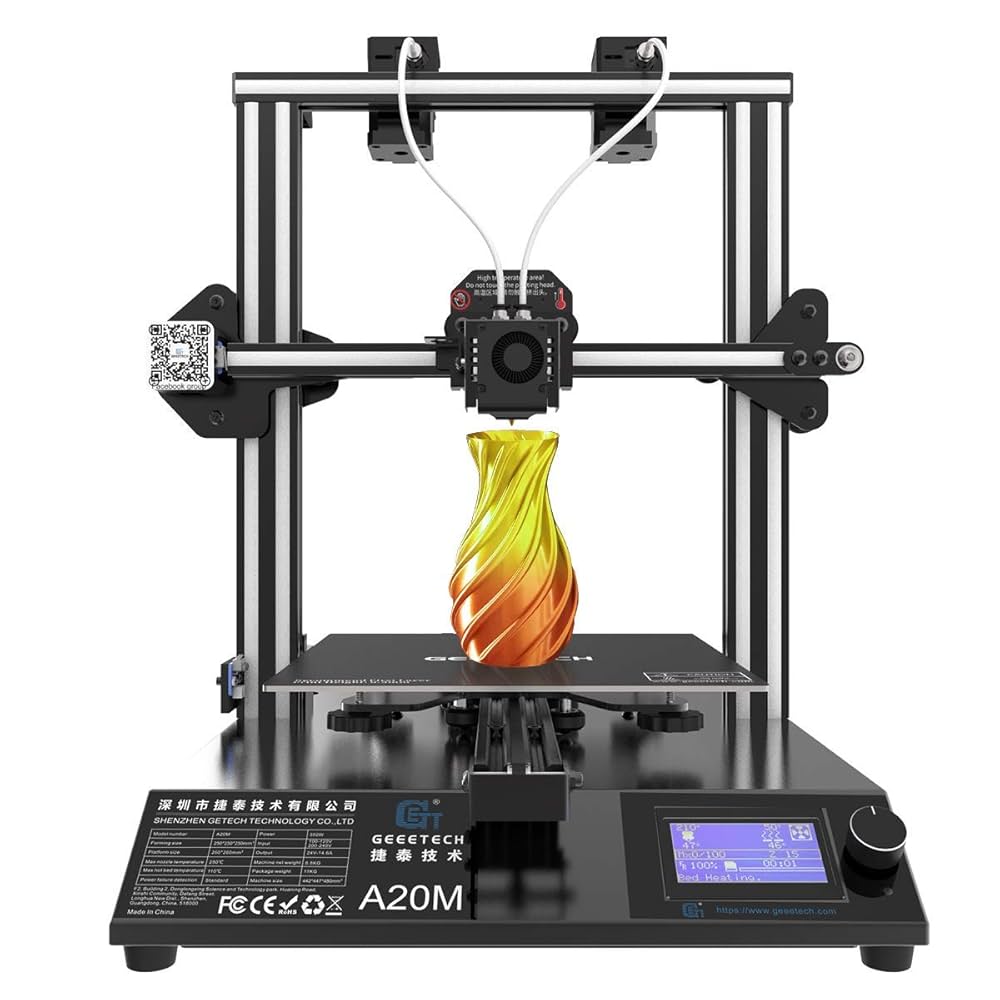

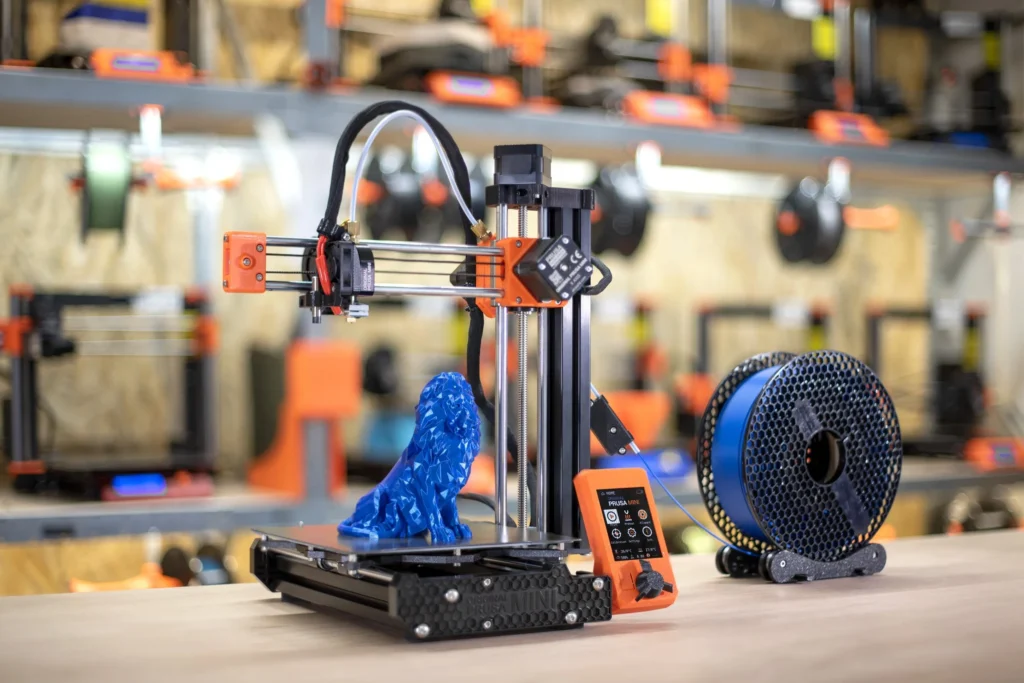

Extrusion → A heated nozzle extrudes melted filament (e.g., PLA, PETG, ABS) in a controlled pattern (used in FDM printers).

4. Object Creation

Layers are stacked until the complete 3D object is formed.

Some objects require post-processing such as cleaning, curing, sanding, or painting to achieve the desired finish.

Key Advantages of 3D Printing

Complex Geometries

Capable of producing highly intricate and customized shapes that traditional manufacturing cannot achieve (e.g., lattice structures, organic designs, internal channels).

Lower Costs

No expensive molds or tooling required.

Low fixed setup costs make it accessible for startups, students, and small businesses.

Reduced Waste

Additive manufacturing builds objects layer by layer, using only the material needed.

Much more sustainable compared to subtractive methods (like CNC machining), which cut away excess.

Prototyping

Rapid prototyping lets engineers test designs quickly.

Reduces product development time and allows faster innovation.

Customization

Products can be tailored to individual needs (e.g., personalized medical implants, custom-fit shoes, unique jewelry).

Applications of 3D Printing

Healthcare

3D printing is revolutionizing medicine with prosthetics, surgical models, and even bio-printed tissues. Custom implants designed for individual patients are improving recovery rates and reducing costManufacturing

Industries are using 3D printing for prototyping, tooling, and even full-scale production. This cuts down material waste and shortens product development cycles.Education

Students are using 3D printers in classrooms to bring abstract concepts to life, from printing molecular structures to historical artifacts.Architecture & Design

Architects and designers now create intricate models quickly and affordably, helping clients visualize their projects before construction begins.